Future of Automotive Polyolefin (PO) Compounds Market $9.30Bn 2024 to $13.12Bn 2032 – Next-Gen Vehicle Design

Technical and regulatory shifts in Japan and the U.S. reshape growth of Polyolefin compounds in the automotive industry USD 13.12 Bn by 2032 worldwide.

U.S. & Japan Automotive Polyolefin Compounds Market to hit $13.12Bn by 2032, driven by lightweight demand booming EV sector.”

AUSTIN, TX, UNITED STATES, September 3, 2025 /EINPresswire.com/ -- Automotive Polyolefin Compounds Market Overview— DataM Intelligence 4Market Research LLP

The global automotive polyolefin compounds market is gaining strong traction as vehicle manufacturers continue to pursue lighter, safer, and more cost-efficient materials. Polyolefin compounds, primarily polypropylene (PP) and polyethylene (PE) blends, have become the backbone of automotive interiors, exteriors, and under-the-hood components. Their versatility, recyclability, and balance between performance and affordability make them indispensable in modern automotive manufacturing.

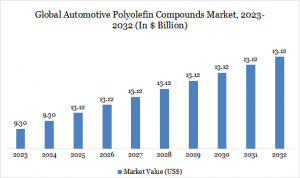

Market Size and Growth

The automotive polyolefin compounds industry was valued at US$ 9.30 billion in 2024 and is projected to climb to US$ 13.12 billion by 2032, advancing at a CAGR of 4.4% between 2025 and 2032.

Get a Sample PDF Of This Report (Get Higher Priority for Corporate Email ID):- https://www.datamintelligence.com/download-sample/global-automotive-polyolefin-compounds-market

Market Dynamics

1. Lightweighting & Fuel Efficiency

• Automotive OEMs are under intense regulatory pressure to reduce vehicle emissions. Polyolefin compounds are up to 30% lighter than conventional materials such as PVC or ABS, directly contributing to lower fuel consumption and extended EV range. For example, replacing metal with polyolefin-based bumpers, dashboards, and door panels can save hundreds of kilograms across a vehicle’s lifecycle.

2. Shift Toward Electric Vehicles (EVs)

• The EV transition is fueling new opportunities for polyolefin compounds. Battery housings, thermal management components, and high-voltage cable insulation increasingly use modified PP and PE formulations due to their excellent dielectric strength, thermal stability, and flame retardancy. With EV sales projected to represent over 45% of new vehicle sales by 2030, demand for advanced polymer solutions is accelerating.

3. Sustainability & Recyclability

• Automakers are pledging net-zero targets, which has increased reliance on recyclable polyolefin compounds. Recycled PP and PE blends are now being incorporated in non-critical parts such as trunk liners, wheel arch liners, and underbody shields. Several OEMs have adopted closed-loop recycling systems, where manufacturing scrap is reprocessed into high-quality polyolefin materials, reducing both cost and environmental footprint.

4. Cost Advantages & Processing Flexibility

• Polyolefin compounds are not only cheaper compared to engineering plastics but also offer high design flexibility. Their ability to be injection-molded, extruded, or blow-molded enables efficient mass production of complex automotive parts with reduced cycle times.

Market Segmentation

By Type

• Polypropylene (PP): Dominant segment; used in bumpers, dashboards, and consoles due to toughness and lightweight properties.

• Polyethylene (PE): Used in fuel tanks, insulation, and interior trim due to chemical resistance and flexibility.

• TPO & TPV (Thermoplastic Olefin/Elastomers): Gaining traction for weather seals, body panels, and under-hood parts thanks to their durability and soft-touch properties.

By Application

• Interior Components: Dashboards, door trims, seat backs, and consoles.

• Exterior Components: Bumpers, fenders, and body panels.

• Under-the-Hood Applications: Air intake manifolds, battery components, and fluid reservoirs.

By Vehicle Type

• Passenger Cars: Largest consumer segment; emphasis on aesthetics and safety.

• Commercial Vehicles: Increasing use for durability and cost-effectiveness.

• Electric Vehicles: Fastest-growing segment; demand for high-performance, heat-resistant materials.

Buy Now & Unlock 360° Market Intelligence:- https://www.datamintelligence.com/buy-now-page?report=global-automotive-polyolefin-compounds-market

Regional Analysis

• Asia-Pacific: The dominant market, led by China, Japan, and India. Rising vehicle production and EV adoption, coupled with government policies favoring lightweight and sustainable materials, are driving growth.

• North America: Significant demand from EV manufacturing hubs in the U.S., combined with stringent CAFE (Corporate Average Fuel Economy) regulations.

• Europe: Strong push toward circular economy practices. The EU End-of-Life Vehicle Directive mandates recovery and recycling of materials, creating demand for recyclable polyolefin compounds.

• Middle East & Africa: Emerging opportunities in lightweight commercial vehicles and aftermarket applications.

Key Players in the Market

1. LyondellBasell Industries

2. Borealis AG

3. SABIC

4. ExxonMobil Corporation

5. Mitsui Chemicals Inc.

6. Sumitomo Chemical Co., Ltd.

7. Dow Inc

8. INEOS Group

9. Washington Penn Plastic Co., Inc.

10. RTP Company

Key strategies include:

• Expanding compounding facilities closer to OEM hubs.

• Developing bio-based and recycled polyolefin solutions.

• Strategic alliances to penetrate the EV materials market.

DataM Intelligence Insights & Recommendations

According to DataM Intelligence, the automotive polyolefin compounds market will continue its growth trajectory with a strong CAGR through 2032. The shift toward electric vehicles, combined with increasing sustainability mandates, is set to redefine material demand.

Recommendations from DataM:

• Invest in Advanced Polyolefin Compounds – Companies should focus on flame-retardant and thermally stable formulations tailored for EV applications.

• Leverage Recycling Technologies – Adopting closed-loop and chemical recycling solutions will help OEMs meet circular economy goals.

• Regional Expansion – Targeting Asia-Pacific markets, particularly China and India, will be critical given their dominance in automotive production.

• Collaborate with OEMs – Building partnerships with automakers for co-development of materials ensures alignment with evolving design and regulatory needs.

Conclusion

The automotive polyolefin compounds market is evolving into a critical enabler of lightweighting, sustainability, and electrification in the automotive sector. With rising regulatory pressures and accelerating EV adoption, demand for innovative, cost-efficient, and recyclable polyolefin compounds will continue to grow. Market players that align with these trends and invest in advanced R&D, regional capacity expansion, and circular economy solutions will be best positioned to capture long-term value.

People Also Ask For Related Reports in DataM Intelligence

Automotive Thermoplastic Compounds Market

Polypropylene Compounds Market

Sai Kiran

DataM Intelligence 4Market Research LLP

+1 877-441-4866

sai.k@datamintelligence.com

Visit us on social media:

LinkedIn

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.